- sales@fokca.com info@fokca.com

- WhatsApp: +86 150 5749 1870

What is a Polyolefin Tubing

Polyolefins are an important type of polymer formed through polymerization reactions of olefin monomers. Typically, they refer to a group of thermoplastic resins obtained from α-olefins such as ethylene, propylene, 1-butene, 1-pentene, 1-hexene, 1-octene, 4-methyl-1-pentene, and certain cyclic olefins through homopolymerization or copolymerization. They are commonly abbreviated as PO.

Polyolefins possess favorable physical properties and chemical stability, making them widely used in plastics, rubber, fibers, and other fields.

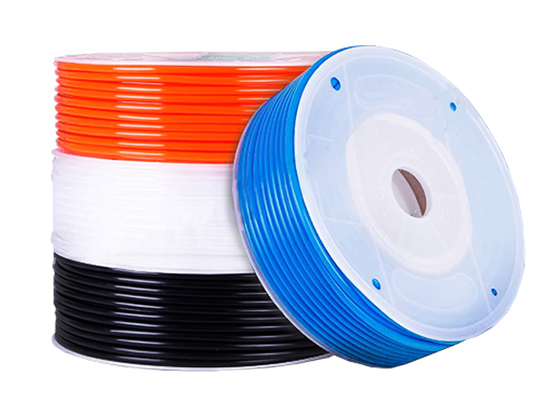

Types of Polyolefins Tubings

Due to their abundant raw materials, low cost, easy processability, and excellent overall performance, polyolefins are the largest-produced and extensively used class of polymers.

The most common types of polyolefin tubings include Low-Density Polyethylene (LDPE) tubings, Linear Low-Density Polyethylene (LLDPE) tubings, Polypropylene (PP) tubings, and Ethylene-Vinyl Acetate (EVA) Copolymer tubings.

Performance Characteristics of Different Types of Polyolefins

◆LDPE Low-Density Polyethylene Tubing

Low-density polyethylene, also known as high-pressure polyethylene (LDPE), is the lightest variety of polyethylene resin, appearing as milky white, tasteless, odorless, non-toxic, and non-glossy waxy particles.

It possesses good flexibility, elongation, electrical insulation, transparency, processability, and some degree of breathability. It exhibits relatively good chemical stability, being resistant to alkalis and general organic solvents.

◆LLDPE Linear Low-Density Polyethylene Tubing

Linear low-density polyethylene (LLDPE) is formed by copolymerizing ethylene with a small amount of α-olefin, resulting in a molecular structure with very short copolymer monomer side chains attached to the linear ethylene main chain.

Linear low-density polyethylene is a milky white granule that is non-toxic, tasteless, and odorless, with a density ranging from 0.918 to 0.935g/cm3.

Compared to LDPE tubing, it has a higher softening temperature and melting temperature, with advantages such as greater strength, good toughness, rigidity, heat resistance, and cold resistance. It also exhibits good environmental stress cracking resistance, impact strength, tear strength, and resistance to acids, alkalis, organic solvents, etc., making it widely used in industrial, agricultural, medical, sanitary, and daily life products.

◆PP Polypropylene Tubing

PP polypropylene has a lower heat deformation temperature (100°C), low transparency, low glossiness, and low rigidity, but it has stronger impact resistance. The impact strength of PP increases with the increase of ethylene content. The Vicat softening temperature of PP is 150°C. Due to its high crystallinity, this material exhibits good surface stiffness and scratch resistance.

Polypropylene tubing is non-toxic, corrosion-resistant, non-scaling, heat-resistant, and corrosion-resistant, with smooth inner walls and lightweight. They are mainly used in urban water supply, chemical industry, petroleum, chlor-alkali, pharmaceuticals, dyes, pesticides, food, metallurgy, electroplating, environmental protection, water treatment, and other industries.

◆EVA Ethylene Vinyl Acetate Copolymer

EVA is an elastic polymer that can produce materials with softness and flexibility similar to rubber. This material exhibits good transparency, glossiness, low-temperature toughness, stress-crack resistance, hot-melt adhesive waterproof performance, and resistance to ultraviolet radiation.

EVA has a distinctive vinegar-like odor and can compete with rubber and ethylene-based polymer products in many electrical applications. It is often used in the production of footwear, packaging materials, industrial products, medical devices, household items, sports equipment, and more.

Quality and Service

Fokca has always adhered to a philosophy that Focus On Keep Customers Ahead, utilizing high-quality raw materials and advanced, reliable production processes. Through rigorous testing, we ensure strict compliance with quality standards, providing products that exceed customer expectations.

Additionally, we focus on delivering personalized technical support and services. Whether you require special designs, brand customization, or solutions for specific application scenarios, Fokca can meet your individual needs.

Choosing Fokca means not only selecting excellent quality but also choosing reliable performance, offering assurance and peace of mind.

For more information on polyolefin tubings, please do not hesitate to Contact us.

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap