- sales@fokca.com info@fokca.com

- WhatsApp: +86 150 5749 1870

A pneumatic system utilizes compressed air and atmospheric pressure to drive various pneumatic system components in order to perform mechanical work across a wide range of industries. These systems rely on the collaboration and coordination of various components of pneumatic to control and regulate airflow to carry out specific tasks. Each pneumatic component serves as a mechanical actuator that is controlled by the system to generate output power. Understanding the operating principles and functions of these components is crucial for utilizing them in a more efficient and effective manner.

Pneumatic systems play a crucial role in various industries by using compressed air to perform mechanical work.

These systems rely on a wide range of Pneumatic Cylinder and accessories that work together to control and regulate the flow of air to perform specific tasks.

Understanding how these components work and their functions can help optimize their use in industrial applications.The following is the complete process operation of the pneumatic system.

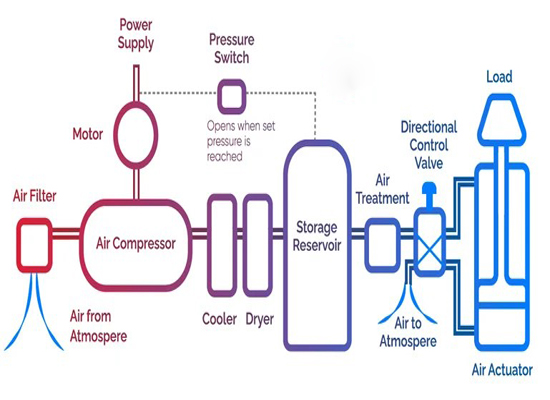

The operation of the entire pneumatic system begins with the air purification process, where a filter is used to remove impurities and particulate matter from the air. The purified air is then delivered to an air compressor, where it is pressurized. The compressor is typically driven by an electric motor and relies on a stable power supply.

During compression, the air heats up significantly, so it must pass through a cooler to reduce its temperature. After cooling, the air enters a drying unit to effectively eliminate excess moisture or water vapor, preventing condensation and corrosion within the system.

To ensure stable system operation, pressure regulation is essential. This is achieved using a pressure valve regulator or pressure controller, which can be adjusted either manually or electronically to maintain the desired pressure level. Once regulated, the compressed air travels through piping systems to various functional components, enabling efficient and unrestricted airflow.

Before reaching the directional control valve, the air may undergo additional filtration or dehumidification. The directional control valve plays a crucial role in guiding the airflow, directing it to the appropriate actuators based on control signals.

At this stage, the pneumatic actuator takes over, converting air pressure into mechanical motion to drive equipment according to the desired operation. For instance, air can power a cylinder, pushing its piston to produce linear or rotary motion.

After completing its work cycle, the exhaust air returns to the directional valve and is safely released back into the atmosphere, completing the closed-loop operation of the system.

A pneumatic system consists of several essential components, Each pneumatic component has a specific function in the system.

◆ Air filters, dryers, and coolers used for processing air or inert gases

◆ Actuators: Convert the compressed air into mechanical motion. Pneumatic cylinders, like rodless cylinders and mini cylinders, are typically used as actuators.

◆ Power: Electric motors, power sources, or diesel engines provide energy to the entire starting system

◆ Air Source Treatment Units: Used to ensure the air is clean, at the correct pressure, and properly lubricated for smooth operation.

◆ Valves: Control the flow and direction of compressed air in the system. Solenoid valves, for instance, are commonly used for automatic control, while manual valves are used for manual control.

◆ Fittings and Tubing: These components connect different parts of the system and ensure that air is delivered efficiently to the right places.

Fokca provid several types of pneumatic components, Each type of pneumatic component with specific functions forms a complete pneumatic system,Can play a role as a whole:

Actuators: Usually referring to pneumatic cylinders,also call air penumatic cylinder. Cylinders come in various models, sizes, functions, and accessories,

ncluding standard cylinders, compact cylinders, guided cylinders, and rodless cylinders. They are one of the most common pneumatic components.

Pneumatic Valves: Including mechanical valves and solenoid valves, used to control the flow of compressed air, directing it to various parts of the system.

Air Source Treatment Components: Typically include filters, regulators, and lubricators, ensuring that the purity, pressure, and humidity of the compressed air meet the operational requirements of the actuators.

Air Motors: Convert compressed air into rotary motion and can be used in various tools and equipment.

Air Compressors: Generate compressed air that powers the entire pneumatic system.

Fokca provides complete customized services for pneumatic components. Contact us for technical support

Pneumatic components offer numerous benefits in industrial applications, including:

Energy Efficiency: Pneumatic systems are energy-efficient because they rely on compressed air, which is readily available and easy to produce.

Clean and Safe: Unlike hydraulic systems, pneumatic systems do not require oils or other fluids, making them cleaner and safer to operate.

Low Maintenance:Pneumatic systems have fewer moving parts and are less prone to wear and tear compared to other mechanical systems, reducing maintenance requirements.

Versatility: Pneumatic components can be used in a wide range of applications, from automation and packaging to robotics and material handling.

Overall, there are various components that make up pneumatic systems,which are widely favored in various industries due to their many advantages.

Their efficiency and stability are particularly critical, allowing them to maintain good operating conditions even under harsh conditions.

With its simple structure and easy maintenance, this type of system is not only user-friendly, but also has cost control advantages.

In which fields are pneumatic systems composed of Pneumatic Components with different types and functions efficiently utilized?

Automation and Robotics: Pneumatic actuators and valves are commonly used in automated systems to perform repetitive tasks like sorting, packaging, and assembly.

Manufacturing: Pneumatic components are used in assembly lines, material handling, and tools like pneumatic drills and impact wrenches.

Packaging: Pneumatic cylinders and actuators help automate packaging processes, including sealing, labeling, and sorting.

Transportation: Pneumatic components are often used in conveyor systems and other material handling equipment.

Medical Equipment: Pneumatic systems are used in medical devices such as ventilators and surgical tools due to their precision and cleanliness.

In conclusion, pneumatic components are integral to a wide range of industrial applications, providing reliable and efficient solutions for various tasks.

Pneumatic systems are widely utilized across various industries due to their exceptional adaptability and high efficiency.

They are particularly well-suited for tasks that demand low cost, rapid response, strong force output, and high precision—such as those found in industrial automation and robotics.

These systems are a preferred solution in sectors like industrial manufacturing, life sciences, and consumer products,

where reliability and superior performance are essential.

In the automotive industry, pneumatic devices play a vital role in automated production lines and air brake systems.

At the same time, pneumatic-powered tools are commonly used across diverse work environments,

delivering the required power and control with precision.

Additionally, pneumatic vacuum technologies are crucial in sectors such as food and beverage processing,

pharmaceuticals, and metallurgy, where they support operations like vacuum packaging and high-precision pick-and-place applications.

Understanding how these components work together helps optimize their use, ensuring the smooth and effective operation of pneumatic systems.

For more details about our industruial pneumatic cylinders, please visit our dedicated pneumatic product website: https://www.fescolo.com/.

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap