- sales@fokca.com info@fokca.com

- WhatsApp: +86 150 5749 1870

Apr 22, 2025

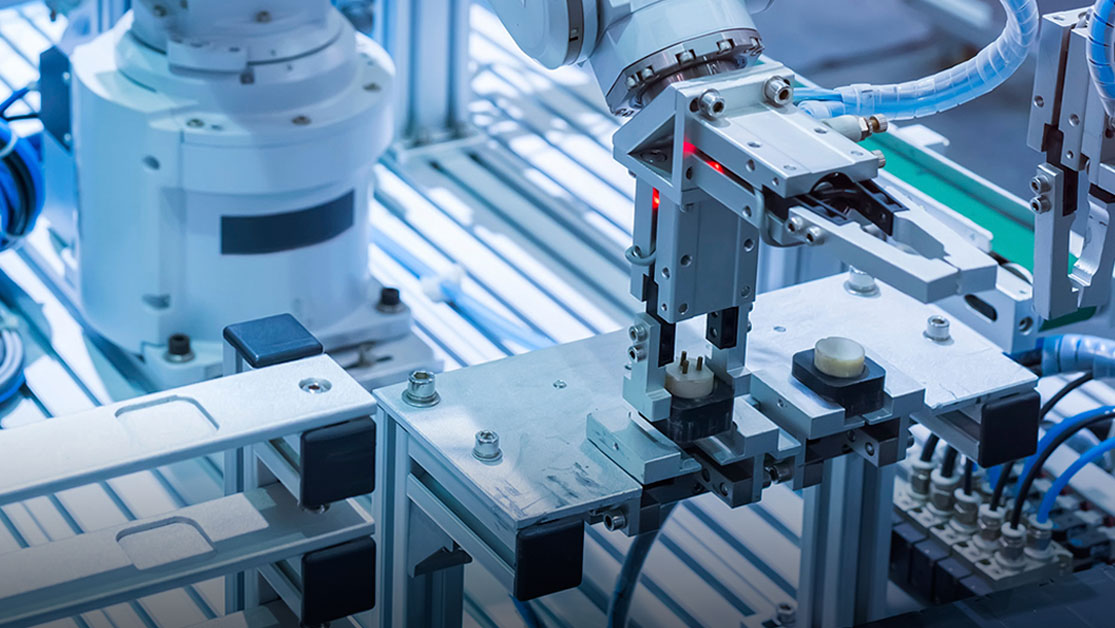

From miniature pneumatic cylinders as small as a finger to heavy-duty cylinders weighing hundreds of kilograms, each type serves a unique purpose.

You’ll find standard cylinders known for their versatility, high precision, and excellent compatibility across systems. For applications requiring double output force and high lateral load resistance, twin-rod guided cylinders are ideal—they feature dual-rod construction for increased stability and prevent piston rotation.

Need to save space? Rodless cylinders offer long stroke lengths without extending the overall footprint. And for tasks involving rotational motion, rotary actuators or pneumatic rotary cylinders efficiently convert linear movement into precise angular positioning.

Despite their differences, all these cylinders are based on the same working principle: harnessing the power of compressed air to drive a piston’s reciprocating motion, converting it into mechanical energy to power automation systems.

This core mechanism is what makes pneumatic cylinders essential components in modern manufacturing, offering tailored solutions across industries like automotive, robotics, food processing, and packaging.

These Standard Cylinders Comply with Universal Industry Standards.Designed for versatile applications with excellent compatibility, our standard cylinders are available in various sizes and stroke lengths.

They reliably meet diverse requirements—from factory automation to mechanical engineering tasks—making them an ideal industrial solution.

This Type of standard air cylinder mainly has several key characters as follow:

Compact & Lightweight: Designed with a smaller footprint and reduced weight compared to traditional cylinders, ideal for space-constrained automation applications.

Standardized Interfaces: Strictly regulated bore sizes, stroke lengths, and mounting hole dimensions ensure cross-brand interchangeability.

Basic Structure: Typically features a single piston rod, double-acting design (compressed air drives piston movement in both directions).

These cylinders adhere to ISO standards for compact pneumatic cylinders, which define unified regulations for:

1)Dimensional specifications

2)Performance parameters

3)Mounting interfaces

| Parameter | Typical Specification (ISO 6431) |

|---|---|

| Cylinder Bore Range | 32mm ~ 100mm |

| Stroke Length | ≤500mm (Longer ones can be customized) |

| Operating Pressure | 0.1 ~ 1.0 MPa |

| Installation Form | Standard Flange or Foot Mounting |

| Cushion Type | Optional Air Cushion or Elastic Cushion |

DNC Series、SI Series、DNG Series are standard cylinder types primarily provided by Fokca that complies with ISO standards.

DNC Series

This type of air cylinders is compact and lightweight, suitable for general automation equipment with limited space. The volume is about 20% smaller than ISO 15552 cylinders, but the load capacity is moderate.

SI Series

Thes series of cylinders belongs to the general-purpose high-performance cylinder, with balance accuracy and durability, suitable for medium and long stroke applications, with magnetic switch slots for easy sensor integration.

DNG Series

This type of cylinder belongs to heavy-duty optimization design, enhancing impact resistance and suitable for high-frequency, high load scenarios (such as punching machines). Optional hydraulic buffer (DNG-H series) to reduce end impact.

As a globally renowned manufacturer of pneumatic components, its standard cylinder product line is rich, including both international standard models and independently designed characteristic series:

SC series (economical standard cylinder)

This series has a cylinder diameter range of 20-100mm, a more compact structure, a more competitive price, and installation dimensions that are partially compatible with ISO standards

Suitable for cost sensitive general industrial applications and retrofitting of ordinary equipment.

SU series (mini cylinder)

This series of cylinders belongs to the ultra compact design, with a width reduced by 25% compared to ISO standards and a cylinder diameter range of 10-25mm

Suitable for precision equipment with limited space and special dust-proof design

SMC (Japan) is a leading global manufacturer of pneumatic components, with a wide range of standard cylinder product lines covering ISO standard, compact, high-performance, and other series, suitable for various fields of industrial automation.

MBB series cylinder

Built in dual guide rod structure, strong lateral force resistance, suitable for eccentric loads. The piston rod and guide rod are separated, resulting in high motion stability. Repetitive accuracy ± 0.01mm (ultra-high precision, comparable to electric cylinders). The guide rod is made of hard chrome plated or stainless steel, with excellent wear resistance. It can withstand radial loads (dispersed force on the guide rod), and the maximum lateral force can reach 50% of the axial thrust.

CA1 CDA1 series cylinder

Low friction sealing technology, with a speed of up to 1.5m/s (0.5m/s for ordinary cylinders). The starting pressure is as low as 0.02MPa, and the response is sensitive. The service life of the seal is ≥ 30 million cycles (about 10 million cycles for ordinary cylinders). The piston rod is designed to prevent rotation and belongs to oil-free lubrication. Suitable for high-frequency reciprocating motion and clean room equipment.

Mini cylinders are designed for applications with limited space but still requiring reliable pneumatic power sources. Despite its compact size, mini cylinders can provide powerful thrust comparable to their size, making them ideal for small automation, medical equipment, and precision engineering tasks.

Micro cylinders are widely used in automation, robotics, and precision equipment to meet the requirements of different industries for miniaturization, precision, and efficiency.

Fokca (Fescolo) offers various types of miniature cylinders, including MA cylinders, MAL cylinders, and DSN cylinders.

MA cylinder: ultra compact cylindrical cylinder body, with a width reduced by 40% compared to standard cylinders, suitable for extremely narrow spaces, single piston rod, double acting design.

MAL cylinder: Built in linear guide rail, significantly improved lateral force resistance (able to withstand radial loads). Integrated piston rod and guide rod, with better motion stability than the MA series.

DSN cylinder: square cylinder body design for easy integration of sensors.

| Comparison Item | MA Series | MAL Series | DSN Series |

|---|---|---|---|

| Core Advantage | Smallest Volume, Lowest Cost | Resistant to Eccentric Load, High Stability | Standardized Design, Adjustable Cushion |

| Precision | ±0.1mm | ±0.05mm | ±0.1mm |

| Load Capacity | Axial Only (≤50N) | Axial + Radial (≤30% Thrust) | Axial (≤150N) |

| Cushion Option | Non-Adjustable Rubber Cushion | Non-Adjustable Rubber Cushion | Adjustable Air Cushion |

| Interchangeability | Non-Standard (Brand Specific) | Non-Standard (Brand Specific) | ISO 6432 (Multi-Brand Universal) |

| Price | Low | Medium | Medium-High |

The Structural composition of this type of pneumatic cylinder:

Single piston: Only one piston moves inside the cylinder.

Double piston rod: A rod extends symmetrically on each side of the piston.

Guiding mechanism: usually equipped with linear bearings or guide rails to enhance the ability to resist lateral forces.

Power mode:

Belongs to a double acting cylinder (the reciprocating motion of the piston is driven by air pressure).

Not belonging to a dual piston cylinder (without two independent pistons).

Fokca offers the following series of dual rod guided cylinders:

MGP Series Dual Rod Cylinder

CXS series double rod cylinder

TN series double rod cylinder

STMB and STMS series sliding bearing cylinders

These four types of cylinders all belong to the dual cylinder structure, with high precision, double output force, and three-axis capability to withstand high lateral loads without rotation, providing better resistance to lateral loads. Different thread types can be provided according to customer requirements, such as BSP, NPT, etc. The piston rod does not require oil lubrication

Magnetically coupled rodless cylinder, referred to as rodless cylinder or rodless actuator, the biggest difference between it and regular cylinder is that there is only a piston in the rodless cylinder and no piston rod, while the regular cylinder contains both a piston and a piston rod.

Fokca offers the following series of rodless cylinders:

CY1B Series Basic Type Rodless Cylinder

Save space, lightweight and has a wide range of applications.Can be used in diversified environments because there is no external leakage.Long strokes available.

CY1R Series Direct Mount Type Rodless Cylinder

Save space, lightweight and has a wide range of applications.Long strokes available.

CY1S Series Slider Type (Slide bearing) Rodless Cylinder

Reduced in weight and Reduced in length.

CY1L Series Slider Type (Ball bushing bearing) Rodless Cylinder

Hollow shafts are used, and centralization of ports on one side makes piping easy. Auto switches can be mounted through the use of special switch rails. Impacts at stroke end due to high speed use can be absorbed, and fine adjustment of the stroke is possible.

The above four models can all use NPT thread and G thread as available as standard.

Pneumatic rotary cylinder, also known as pneumatic rotary actuator, uses compressed air to push the internal rack and pinion, thereby converting linear motion into rotational motion

Fokca offers the following series of pneumatic rotary cylinders:

MSQ Series Rotary Table

CRQ2 Series Compact Rack&Pinion Rotary Table

CRA1 Series Rotary Table

When standard cylinders cannot meet specific application requirements, special cylinders are essential. Fokca (Fescolo) offers customized cylinders designed to meet unique requirements in terms of force, size, stroke length, or environmental conditions. These special cylinders provide the necessary flexibility for industries that require precise control, high performance, and professional solutions, ensuring operational efficiency and reliability.

Fokca offers two types of Stopper Cylinders named RSQ, and RSDQ Series Stopper Cylinder with the following features:

Small size and light weight.

Flexible and precision.

There are more mounting holes on the fixed board

Different thread type can be offered according to customers' requirements, e.g.:BSP, NPT etc.

Self-lubricate on piston rod by oil,which can reduce maintenance costs in the later stage.

Just like LEGO bricks, engineers build automated systems that meet various needs by combining and matching different cylinders. From welding robots in automobile manufacturing plants to sorting devices in beverage filling lines; From precise positioning in machine tool processing to high-speed actions in logistics sorting Cylinders, with their reliable, efficient, and economical characteristics, have become an indispensable source of power for modern industrial automation.

This makes people marvel at how simple physical principles, through clever design changes, can give rise to such a rich and diverse range of application possibilities. This is precisely the charm of industrial automation technology!

What is the main difference between a single acting cylinder and a double acting cylinder?

Single acting cylinders use air pressure to achieve movement in one direction and springs to achieve return, while double acting cylinders use air pressure to achieve movement in two directions.

Can cylinders be used for lifting?

Yes, certain types (such as impact cylinders and tandem cylinders) are designed specifically for heavy-duty lifting and high-strength applications.

Is pneumatic cylinder environmentally friendly?

Cylinders are usually environmentally friendly because they use air (a renewable resource) as power.

How often should the cylinder be maintained?

The maintenance plan may vary, but regular checks for leaks and wear are crucial for achieving optimal performance.

Can cylinders be customized for specific purposes?

Yes, specialized cylinders are tailored to the specific needs of various applications.

You May Interest In

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap