Types of Polyolefin Tubes

Polyolefins are one of the most widely produced and applied types of polymers, known for their abundant raw materials, low cost, ease of processing, and excellent overall performance.

The most common polyolefin tubes include Low-Density Polyethylene (LDPE) tubes, Linear Low-Density Polyethylene (LLDPE) tubes, Polypropylene (PP) tubes, and Ethylene-Vinyl Acetate (EVA) copolymer tubes.

Performance Characteristics of Different Types of Polyolefins

◆ PE (Polyethylene) Tubes

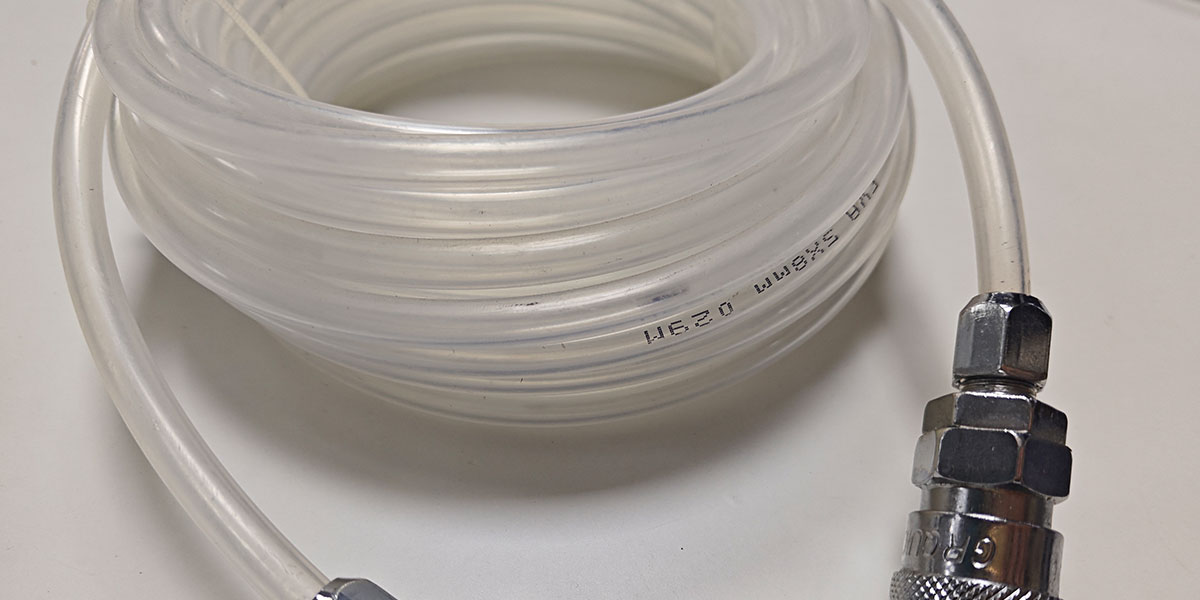

Polyethylene tubes are versatile and lightweight, well-known for their excellent chemical resistance and durability.

They are typically used for fluid transfer applications involving water, air, and other non-corrosive fluids.

PE tubes are flexible, easy to install, and have good impact resistance, making them ideal for industries like agriculture, construction, and automation.

Available in various sizes, PE tubes are an economical choice for low- and medium-pressure systems.

◆ LDPE (Low-Density Polyethylene) Tubes

LDPE, also known as high-pressure polyethylene, is the lightest variety of polyethylene resin, with a milky appearance, odorless, non-toxic, and waxy granular texture.

It offers good flexibility, elongation, electrical insulation, transparency, processability, and a certain level of permeability. LDPE has better chemical stability, alkali resistance, and is resistant to general organic solvents.

◆ LLDPE (Linear Low-Density Polyethylene) Tubes

Linear Low-Density Polyethylene (LLDPE) is a copolymer made by combining ethylene with a small amount of α-olefins.

The molecular structure of the copolymer consists of very short side chains attached to the linear ethylene backbone.

LLDPE is a milky white granule with a non-toxic, odorless, and tasteless composition.

It has a density range of 0.918 to 0.935g/cm3. Compared to LDPE tubes, LLDPE has a higher softening temperature, greater strength, and superior toughness, rigidity, heat resistance, and cold resistance.

LLDPE tubes also exhibit excellent environmental stress crack resistance, impact strength, tear resistance, and resistance to acids, alkalis, and organic solvents, making them ideal for industrial, agricultural, medical, sanitation, and daily applications.

◆ PP (Polypropylene) Tubes

Polypropylene tubes have a relatively low thermal deformation temperature (100°C), low transparency, gloss, and rigidity but are highly impact-resistant.

The impact strength of PP increases as the ethylene content rises, and the Vickers softening point of PP is 150°C. Due to its high crystallinity, PP offers good surface stiffness and scratch resistance.

Polypropylene tubes are non-toxic, corrosion-resistant, non-scaling, heat-resistant, and have smooth inner walls, making them suitable for applications in municipal water supply, chemicals, petroleum, chlor-alkali, pharmaceuticals, dyes, pesticides, food processing, metallurgy, electroplating, environmental protection, and water treatment.

◆ EVA (Ethylene-Vinyl Acetate) Copolymer Tubes

EVA is a flexible polymer that produces soft and resilient materials similar to rubber. It has excellent transparency, gloss, low-temperature toughness, stress crack resistance,

hot-melt waterproofing properties, and UV resistance.

EVA has a unique vinegar-like odor and competes with rubber and vinyl polymer products in many electrical applications.

It is commonly used in the production of footwear, packaging materials, industrial products, medical devices, household items, and sports equipment.

Quality & Service

Fokca always adheres to the philosophy of "focusing on customers and keeping them ahead," using high-quality raw materials and advanced, reliable production processes.

Through rigorous testing, we ensure strict compliance with quality standards, providing products that exceed customer expectations.

Additionally, we focus on offering personalized technical support and services.

Whether you need special designs, brand customization, or solutions tailored to specific application scenarios, Fokca can meet your individual needs.

Choosing Fokca means choosing outstanding quality and reliable performance, providing peace of mind and assurance.

For more information on polyolefin tubing, please contact us.